Ensure that the you are using suitable hold down methods such as double sided tape, masking tape + super glue or clamps over a small area. Up cuts have a tendency to pull up the material you are cutting.

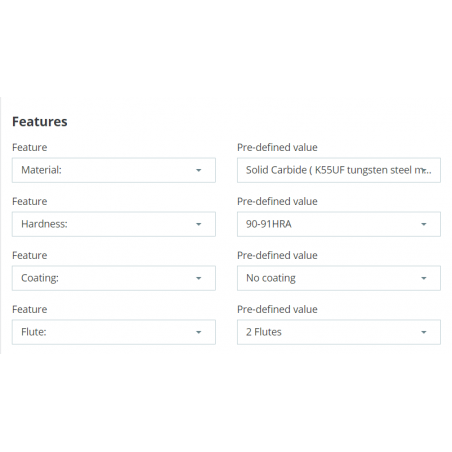

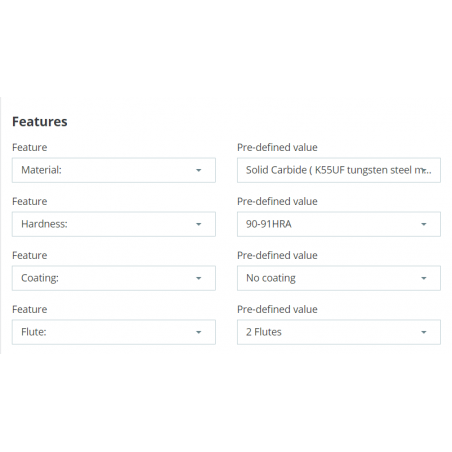

Plastics (ABS, acrylic, HPDE etc) - Good. These cutters are primed for high efficiency cutting on woods but do leave a burr on the top of your material and a clean finish on the bottom side. A benefit of a 2 flute up cut is that you can drive your bit twice as fast in feed than a single flute although with 2 flutes now occupying the cutter, the chip ejection is not as good. Also known as “fishtail” or spiral up cut, these bits are like a traditional drill bit in which the spirals direct chips up. To reduce rewelding, ensure your bit doesn’t heat up by driving your feed rate high and router RPM low.Ī 2 flute up cutter sports two cutting edges or “teeth” which now means that for every rotation of the bit, two edges will be cutting your material. Plastics (ABS, acrylic, HPDE etc) - Excellent.

As these bits are purposely aggressive, using these bits on laminated woods like ply or softwoods would tear up your material and leave a heavily burred finished. The combination of the two means that when cutting plastics, you avoid the nasty occurance of “chip rewelding” where plastic upon cutting heats up to the point it solidifies behind the cutter, rather than ejecting nicely. Also know and single or “O” flute, the one toothed up cutter allows for maximum chip ejection compared to any other bit and generates the least amount of heat. There is only really one bit that you would want to attempt on plastics and that is the 1 flute up cut. OK, we got that out of the way, let's go! Also, what works for others, might not for you of which therefore Adam's Bits is not liable for bit breakages and undesirable consequences as a result of using this guide. These are because we've gone through some extensive testing under various conditions. Just a caveat, the achievable results published here are based on the bits sold by Adam's Bits.

2 Flute TAPERED Ball Nose Carbide Mill (for 3D Carving).  2 & 3 Flute TCT STRAIGHT Carbide Tipped End Mill. 2 Flute BALL NOSE Carbide Mill (for 3D Carving). I have written a bit by bit guide on the most popular profiles available and will give you an overview of their capabilities. So you got your new CNC and have no idea what the difference between a straight cut and a compression cutter is? That's ok, I was the same and I am sure everyone goes through the same motions.

2 & 3 Flute TCT STRAIGHT Carbide Tipped End Mill. 2 Flute BALL NOSE Carbide Mill (for 3D Carving). I have written a bit by bit guide on the most popular profiles available and will give you an overview of their capabilities. So you got your new CNC and have no idea what the difference between a straight cut and a compression cutter is? That's ok, I was the same and I am sure everyone goes through the same motions.

0 kommentar(er)

0 kommentar(er)